Largest geotechnical engineering, drilling, and materials testing firm in India and Africa.

Founded in 2002, SK Geotechnical Services is a full-service firm dedicated to meeting the needs of our clients and creating solutions to the complex issues facing today’s construction projects.

Our goal is to be the best geotechnical engineering firm in the region. We listen to your needs, become part of your team, and commit the necessary resources and equipment to ensure success.

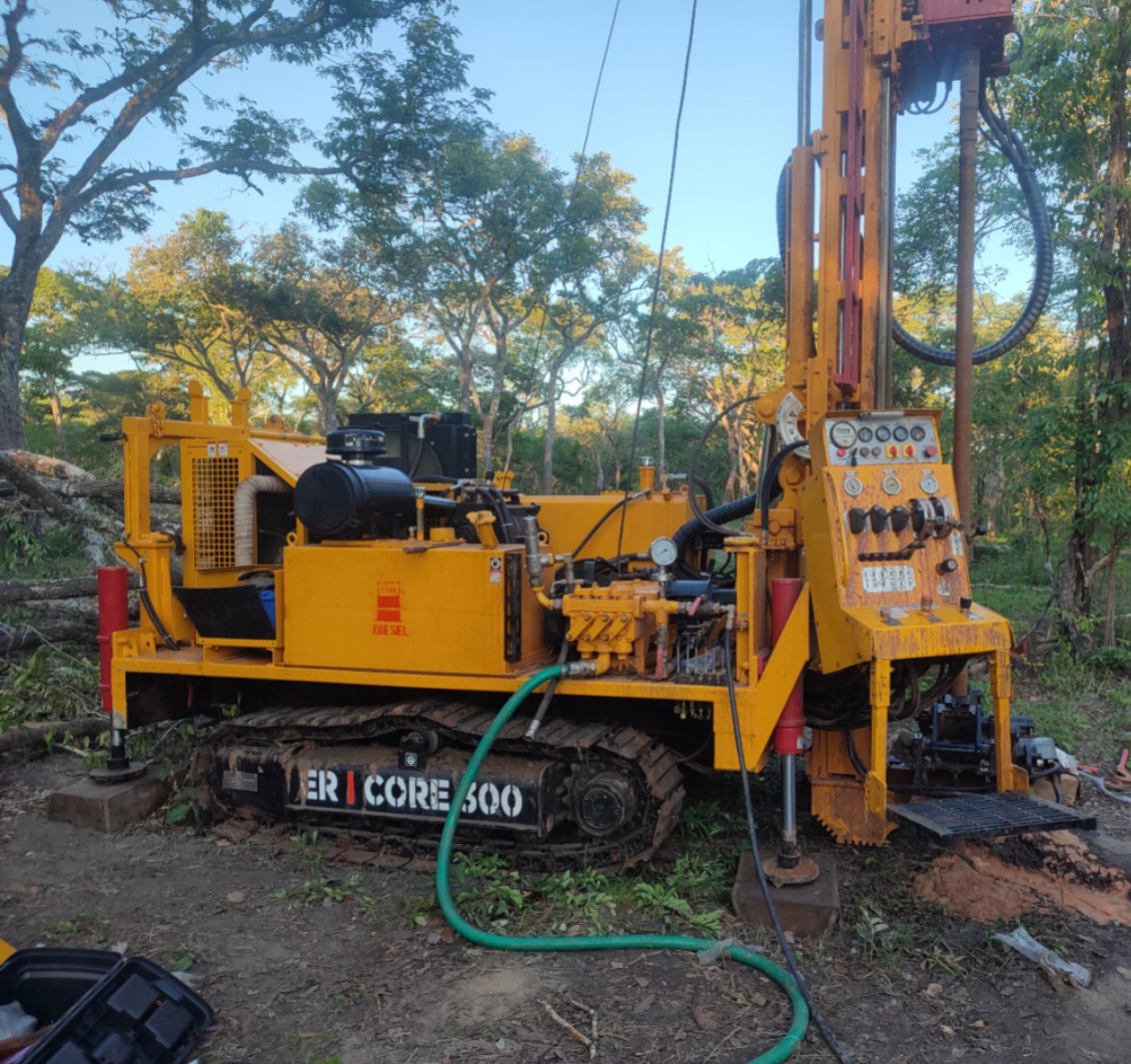

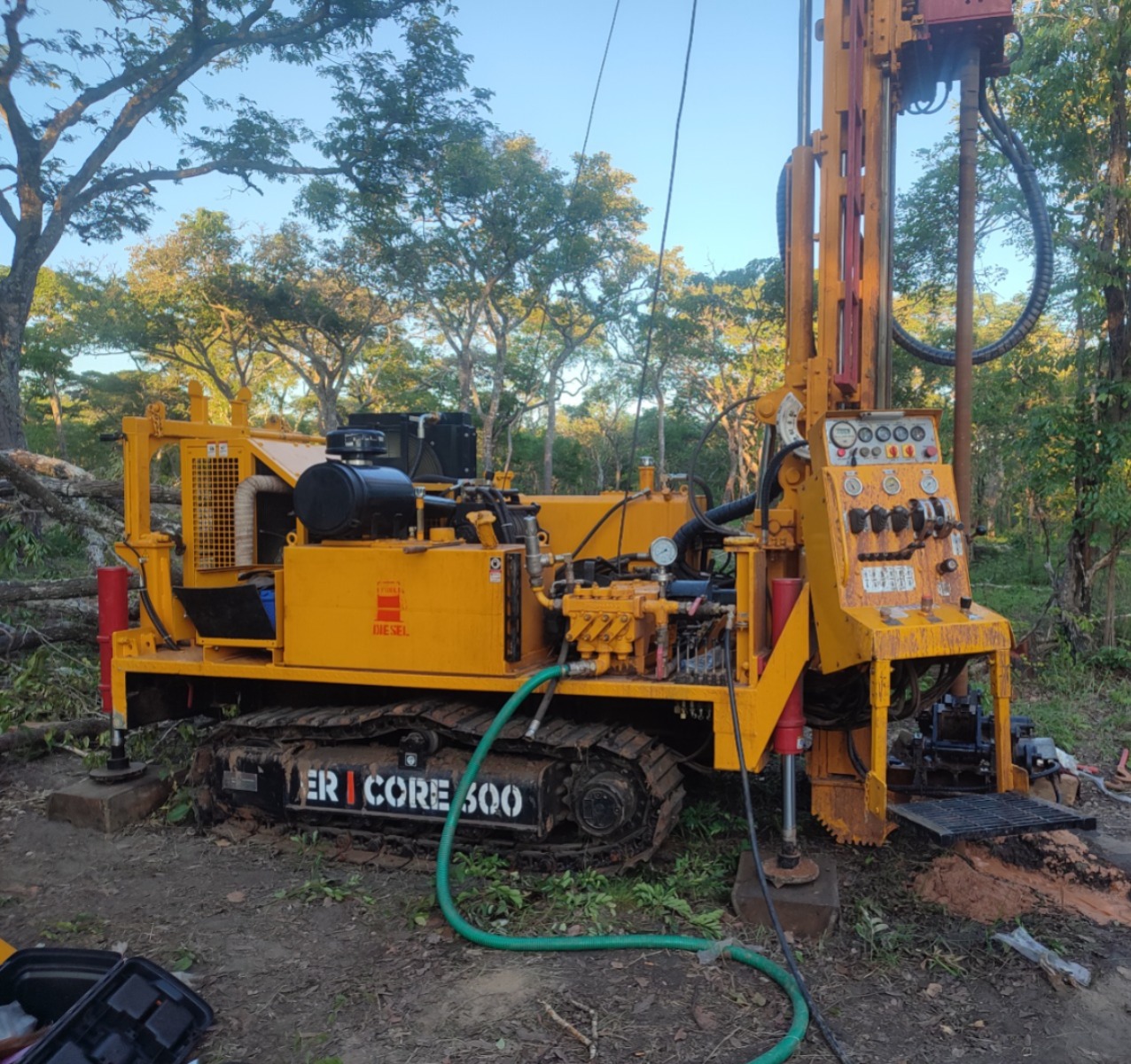

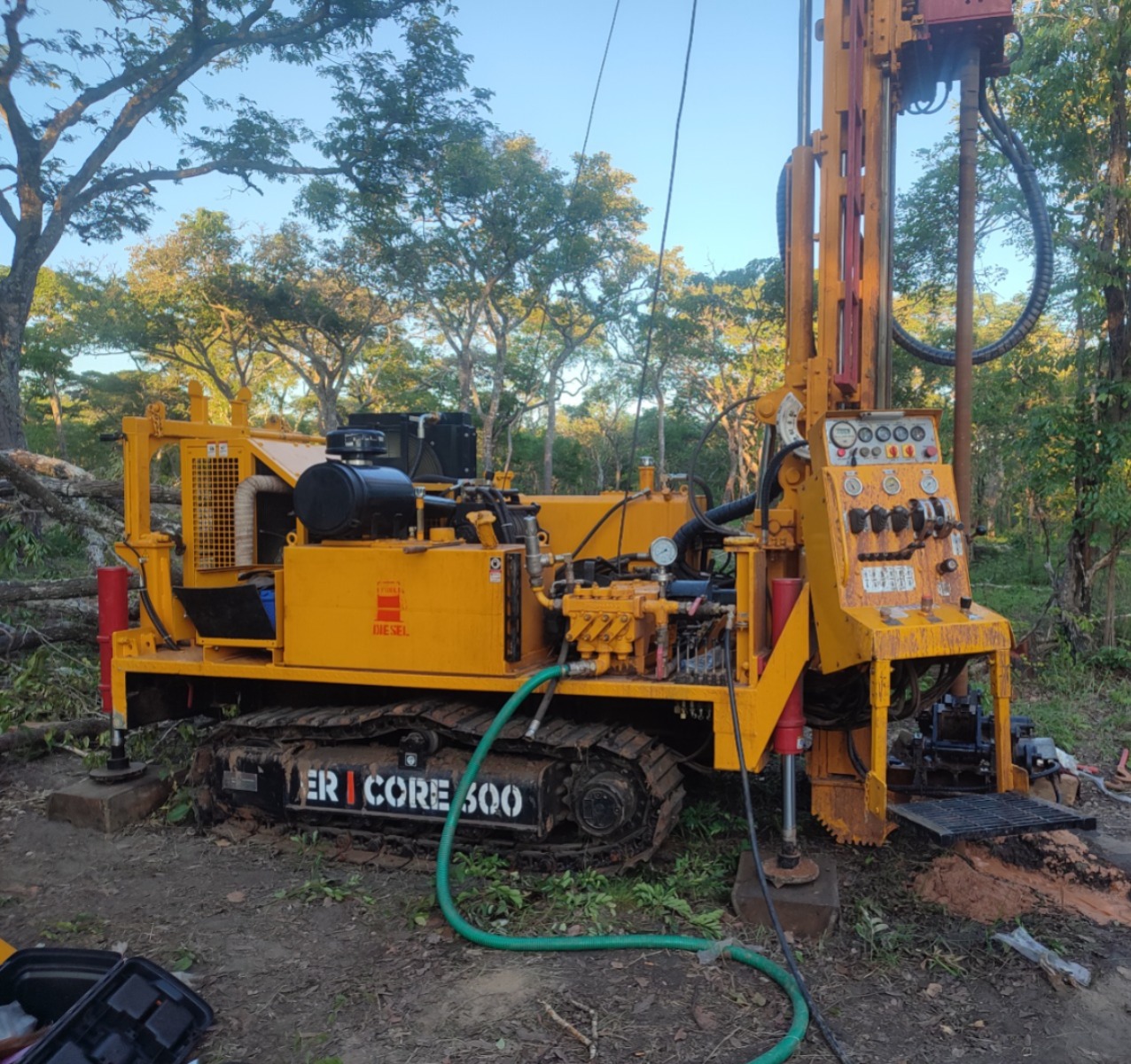

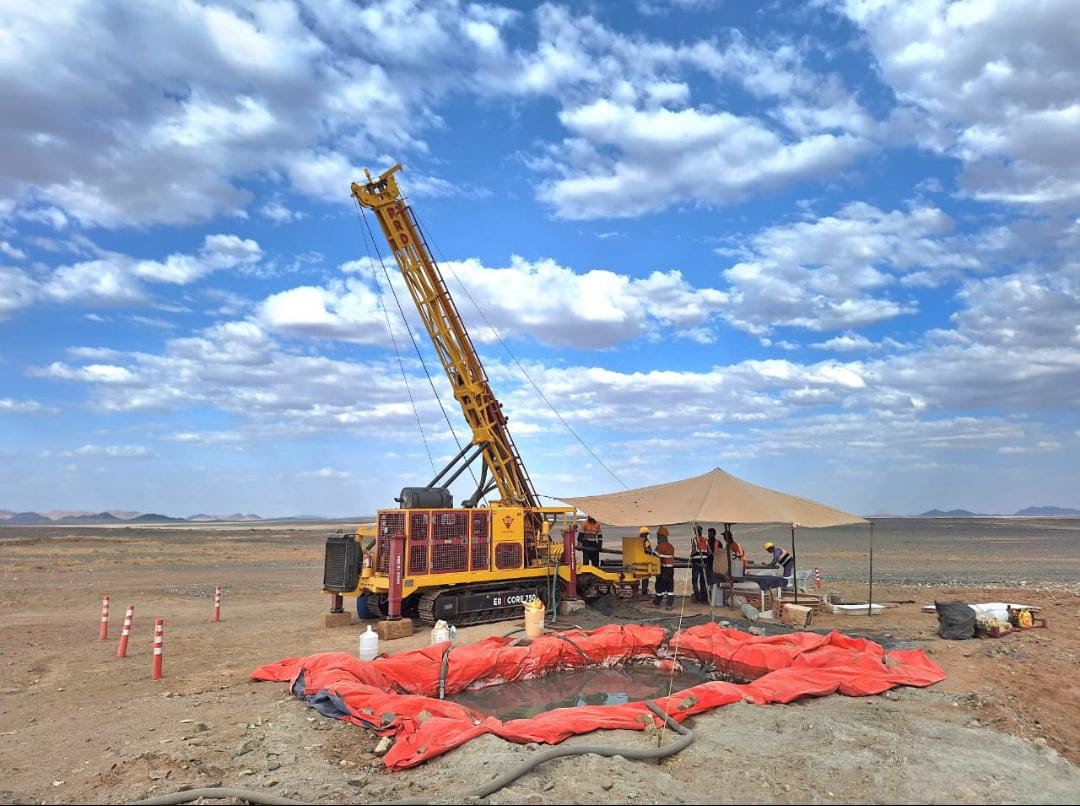

We own and operate a fleet of fully equipped blast hole drill rigs, providing reliable drilling services across India and Africa.

Our exploration drill rigs help discover and analyze underground resources efficiently, ensuring precise and safe operations.

We provide advanced water well drilling solutions to ensure sustainable water supply for communities and industries.

We provide the very best geotechnical engineering, drilling, and construction materials testing services, starting by listening to your needs and fully understanding your project.

Our professionals become an integral part of your design and construction team, mobilizing with our own drill rigs to complete the work efficiently.

We evaluate subsurface soil, bedrock, and groundwater, providing reliable design parameters while maintaining strong communication throughout the project.

Blast Hole Drilling is a technique used in mining whereby a hole is drilled into the surface of the rock, packed with explosive material, and detonated. The aim of this technique is to induce cracks in the inner geology of the surrounding rock, in order to facilitate further drilling and associated mining activity.

The initial hole into which the explosives are packed is known as the “blast hole”. Blast hole drilling is one of the primary surface drilling techniques employed in mining operations today. It is traditionally used wherever the mining company wants to explore the mineral composition or potential mineral yield of the area.

We are one of the leading blast hole drilling companies operating in most of the major coal mining and Iron ore projects across various regions of India. We have extensive experience of around 15 years in blast hole drilling with a fleet of more than 80 rigs.

Our team of experts carefully manages each step of the blast hole drilling process to ensure safety and quality of outcome.

During these years, we have designed many tailored solutions for customers based on their needs to meet optimal outcomes. To meet new challenges and adapt modern technologies, we have set up our own design and innovation team to manufacture blast hole drill rigs in-house.

Our blast hole rigs are capable of drilling holes with diameters ranging from 100 mm to 127 mm to a maximum depth of 20 meters.

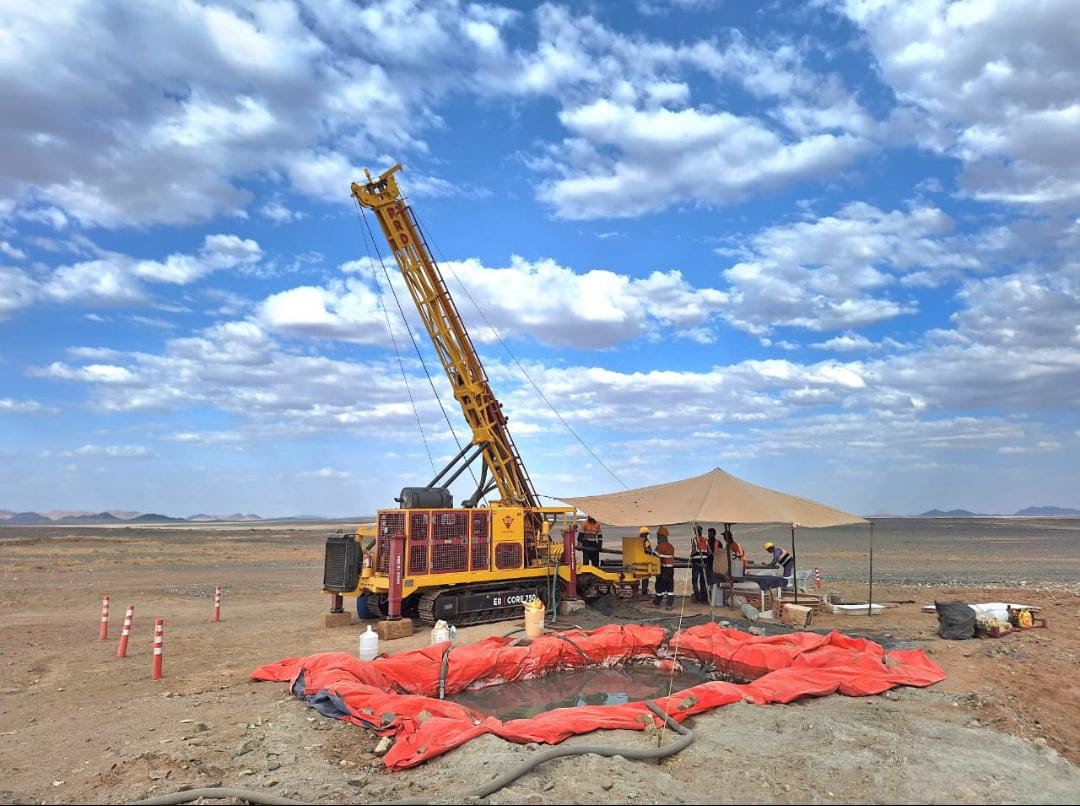

Africa’s mineral and oil wealth is enormous. The continent has 30 percent of the world’s minerals and proven oil reserves equivalent to 10 percent of global stock. Yet, much of the natural wealth remains unexplored. Properly harnessed and managed, Africa’s mineral wealth could be transformational for the continent’s future.

Exploration drilling is a procedure in which several test holes are drilled to evaluate the contents of the ground in a particular area. Drilling is used to obtain detailed information about rock types, mineral content, rock fabric, and the relationship between rock layers near the surface and at depth.

Geologists use exploration drilling to learn more about geologic strata, without the specific goal of exploiting mineral resources. Samples provide critical information about a site’s geological composition and history.

We specialize in the following drilling services:

Each method is carefully chosen based on the site requirements and geological conditions to ensure accurate sampling and analysis.

Auger drilling uses a blade mounted on a rotating string of rods. This method is suitable for shallow boreholes and requires little site preparation. Our Auger drills are capable of drilling Ø 140mm up to 90 meters depth.

Air-core drilling is a reverse circulation technique that produces short rock cores for analysis. Our rigs can drill Ø 75mm to depths of 60-120 meters using truck or track-mounted rigs.

RC drilling uses piston impacts to break rock efficiently. It allows deeper, faster drilling and delivers uncontaminated samples. Our rigs can drill Ø 115-140mm to depths of 400 meters.

Grade control involves drilling holes in pits to check ore quality and reduce waste rock. Our rigs can perform GC drilling up to 40 meters with Ø 125-140mm holes, using modern equipment to ensure efficiency.

Africa is a continent with wildly diverse geology where clean, safe drinking water is scarce. Water is the foundation of life and still today, too many people spend their entire day searching for it. Nearly 1 billion people in the developing world don’t have access to it.

Drilling Water Wells in Africa requires hands-on experience. It is important to partner with experts who have successfully done it repeatedly, including hydrogeologists and experienced drilling crews.

Drilled water wells with traditional hand pumps provide sustainable solutions to rural communities’ water problems. They are well protected from surface water contamination and can reach deep aquifers, ensuring a reliable water supply.

SK Geotechnical Services is known for its water well drilling expertise in India and Africa. With over 15 years of experience, our team uses modern equipment capable of drilling up to 300 meters depth with bore sizes from 165 mm to 330 mm.

Our rigs and teams are designed to efficiently handle complex water well drilling projects while ensuring safety, quality, and reliability.

Have a project or question? Reach out today.